Products

< Product > High Reliability Lead-Free Solder Paste

High resistance to cracking

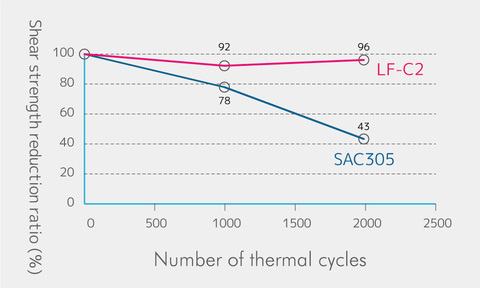

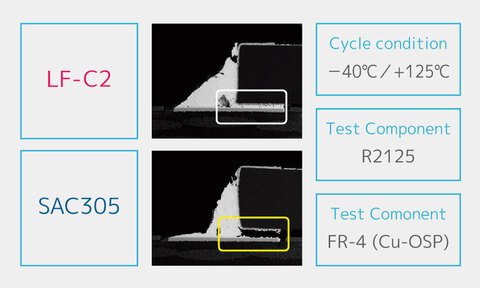

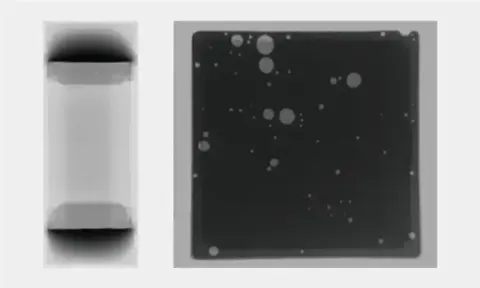

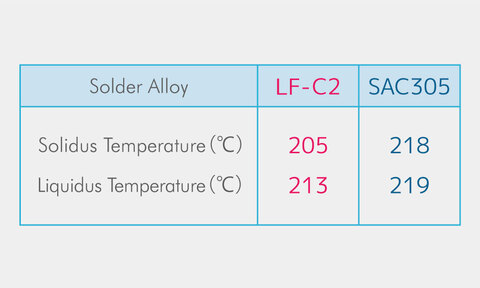

In recent years, lead-free solder materials have been required to have excellent thermal cycle resistance. Hard alloys are preferred because they become less deformed during thermal cycles, but due to their hardness, they cannot absorb forces such as impacts, and the applied forces can apply damage to the joint interface portions and components, causing cracks. LF-C2 has alloy characteristics with excellent heat cycle resistance by optimizing the balance of strength. It also reduces void generation, which is one of the issues of surface mounting.