< Product > General-Purpose, Lead-Free, Flux-Cored Solder

Notable features are flux spattering prevention and improved wetting

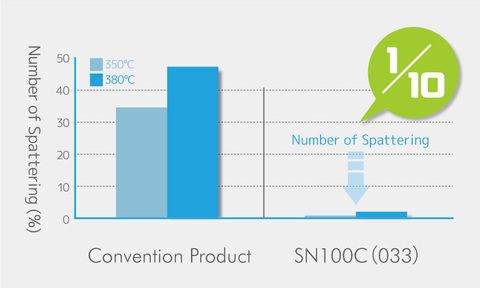

Flux spattering evaluation: " Reduces Flux Spattering in Various Temperature Ranges "

-

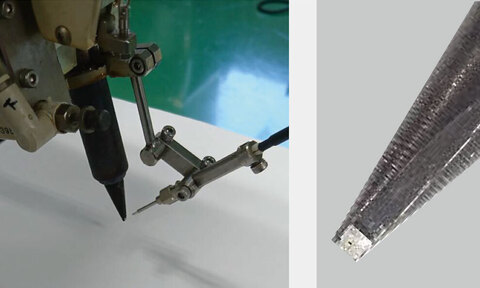

Test Method (additional soldering process) The test was conducted assuming an additional soldering process for repairing a component for which a sufficient amount of solder could not be secured during wave soldering. The product was evaluated at temperatures of 350°C and 380°C.

(Left) Photo taken in the actual test

(Right) Shape of the soldering tip used in the test -

Test Results and Test Conditions Solder : SN100C (033)

Supply Smount : 6.4 mm (wire diameter ⌀ 1.0 mm)

Supply Speed : 20 mm/s

Number of Tested Items : n = 5

Temperature Setting : 350°C, 380°C

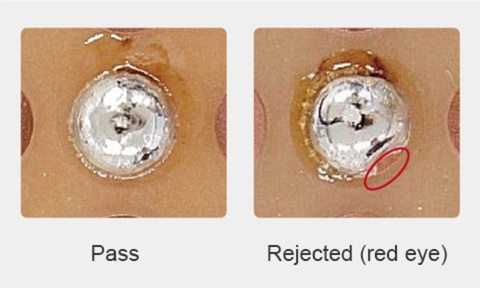

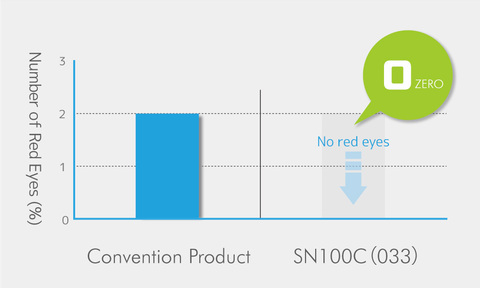

Comparison of red eye generation (comparison of wetting) : " Good wetting prevents red eyes "

-

Testing Method Performed soldering at 30 sections at a speed of 0.5 sec per section and counted the number of red eyes.

-

Comparison of Number of Generated Red Eyes (soldered sections: 30) Solder : SN100C (033)

Supply Amount : 6.4 mm (wire diameter ⌀ 1.0 mm)

Supply Speed : 12.8 mm/s

Temperature Setting : 380°C

Evaluated Circuit Board : Paper Phenol PCB

Land Diameter : 3 mm