Products

< Product > NS-F851 Wave Soldering Flux

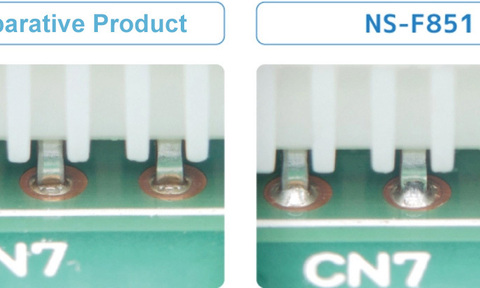

Good barrel fill and topside fillet formation

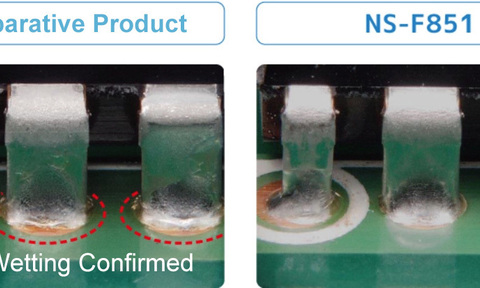

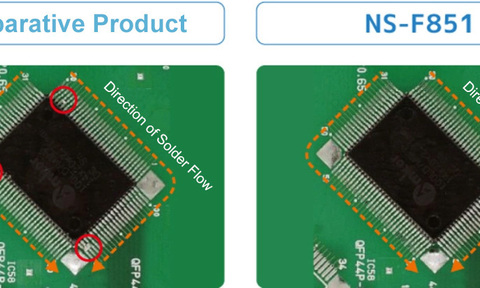

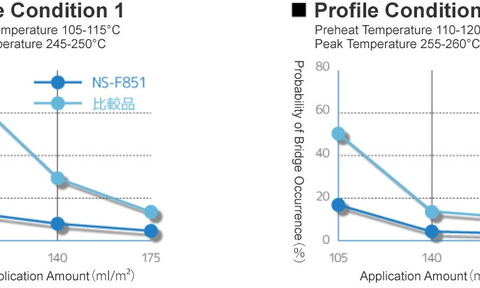

NS-F851 is flux for lead-free wave soldering. It facilitates solder drainage and ensures minimum bridges, thus providing secure mounting in wave soldering. Additionally, this flux allows excellent wetting and reliable solder joints.

Works perfectly with Sn-Cu-Ni solders as well as SAC305

NS-F851 works well with Sn-Ag-Cu solder (SAC305) and Sn-Cu-Ni solder (SN100C) Wave soldering lines running either type of alloy can be converted to NS-F851 with minimal inconvenience compared with an alloy change.