No-Clean Fluxes for PCB Assembly – Product LineUp

| Product number | NS-F850 | NS-F851 | NS-F901 | NS-F902 |

|---|---|---|---|---|

| Application | General purpose | General purpose | General purpose | General purpose / Suitable for Sn-Bi low-temperature solder |

| Features | Excellent solder separation / Excellent wettability | Excellent solder separation / Excellent wettability |

Excellent wettability Completely halogen-free |

Completely halogen-free |

| Flux classification | ROL1 | ROM1(ROL1) | ROM0 | ROM0 |

| Halogen content | Contained | Contained | - | - |

| Halide content | 0.09 mass% | 0.08 mass% | 0.00 mass% | 0.00 mass% |

| Specific gravity | 0.826 | 0.829 | 0.822 | 0.829 |

| Solid content | 16.0 mass% | 15.5 mass% | 15.0 mass% | 15.2 mass% |

| Insulation resistance | ≧1.0×109 | ≧1.0×109 | ≧1.0×1010 | ≧1.0×109 |

NS-F850

- General purpose

- Compatible with spraying and foaming

- Category : ROM1 (ROL1)

- Contains halogen

Excellent wettability, through-hole solder climbing, and solder separation performance.

Excellent wettability, through-hole solder climbing, and solder separation performance.

NS-F850 is an ideal post-flux for lead-free soldering processes of printed circuit boards mounted with chip components and discrete devices.

・Excellent solder separation

・Excellent wettability

・Effective bridge suppression

・Matte surface finish

It provides excellent through-hole solder climbing performance and forms a uniform solder fillet, ensuring highly reliable solder joints.

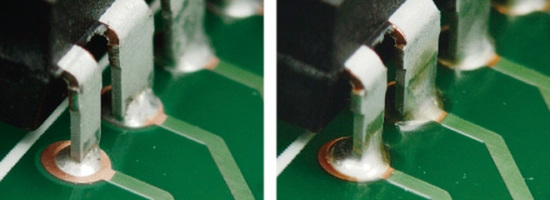

Left : Comparison product (bridging observed)

Right : NS-F850

Handling Precautions

Handling Precautions

・Always perform concentration control when using NS-334 (Dedicated diluent : NS-700).

・Concentration control is not required when using spray application.

NS-F851

- General purpose

- Compatible with spraying and foaming

- Category: ROM1 (ROL1)

- Contains halogen

Excellent solder separation, bridge suppression, and reliable assembly quality

Excellent solder separation, bridge suppression, and reliable assembly quality

NS-F851 is a post-flux designed for lead-free soldering processes.

It offers excellent solder separation and superior wettability. Even on fine-pitch pads, it significantly reduces the occurrence of bridging, contributing to reliable and stable assembly quality in flow soldering processes.

・Excellent solder separation

・Excellent wettability

・Effective bridge suppression

・Improved filter maintenance performance

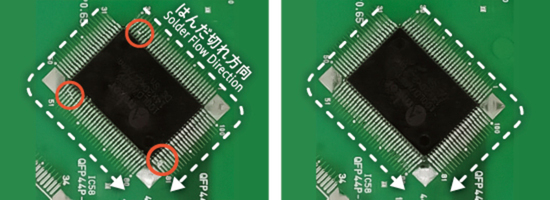

Excellent Solder Separation (Suppresses Bridge Formation)

Excellent Solder Separation (Suppresses Bridge Formation)

Left : Comparison product (bridging observed)

Righ t: NS-F851

NS-F851 provides excellent solder separation properties and effectively suppresses bridge formation, even in fine-pitch assembly conditions.

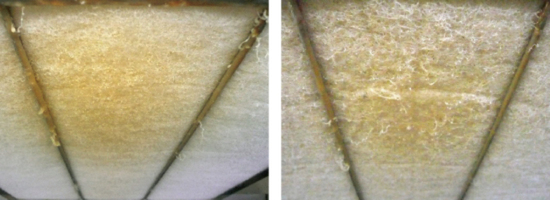

Reduced Fluxer Filter Clogging

Reduced Fluxer Filter Clogging

Left : Comparison product (Primary filter: Day 2)

Right : NS-F851 (Primary filter: Day 4)

Compared to conventional fluxes, NS-F851 reduces fluxer filter clogging by approximately 50%, greatly improving maintenance performance.

NS-F901

- Completely halogen-free

- Compatible with spraying and foaming

- Category : ROM0

- Not contains halogen

Completely Halogen-Free Type.

Matte Finish After Assembly — Helps Prevent Defect Oversight

Completely Halogen-Free Type.

Matte Finish After Assembly — Helps Prevent Defect Oversight

NS-F901 is a highly reliable, completely halogen-free post-flux containing no halogen elements (F, Cl, Br, or I).

By producing a matte solder surface after assembly, it significantly improves the efficiency of visual inspection and helps prevent defects from being overlooked.

・Excellent solder separation

・Excellent wettability

・Effective bridge suppression

・Matte surface finish

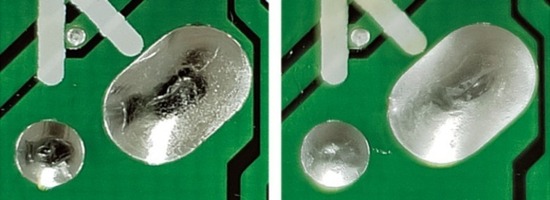

Matte Finish with Reduced Gloss After Assembly

Matte Finish with Reduced Gloss After Assembly

Left : Conventional product

Right : NS-F901

NS-F902

- Completely halogen-free

- Compatible with Sn-Bi low-temperature solder

- Categoty : ROM0

- Not contains halogen

Completely halogen-free.

Also suitable for assembly processes using Sn-Bi low-temperature solder.

Completely halogen-free.

Also suitable for assembly processes using Sn-Bi low-temperature solder.

NS-F902 is a highly reliable post-flux that contains no halogen elements (F, Cl, Br, or I).

It provides excellent solder separation and outstanding wettability, enabling reliable and stable soldering performance.

It is also suitable for wave soldering processes using low-melting-point solders (Sn-Bi systems).

・Excellent solder separation

・Excellent wettability

・Effective bridge suppression

・Improved filter maintenance performance

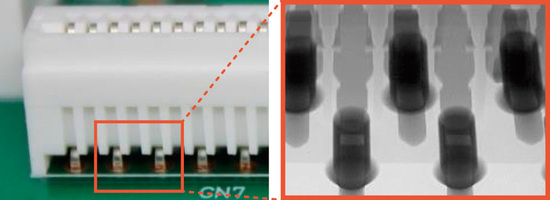

Excellent Wettability (FR-4 Substrate / CN Chidori Connector)

Excellent Wettability (FR-4 Substrate / CN Chidori Connector)

Right : SEM image of solder joints assembled with NS-F902

Through-hole wettability is also excellent.

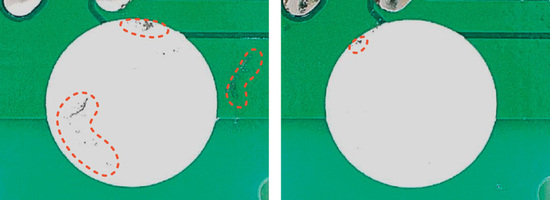

Evaluation with Low-Melting-Point Solder

Evaluation with Low-Melting-Point Solder

Left : Conventional product

Right : NS-F902

When using Sn-Bi solder, NS-F902 effectively suppresses the occurrence of solder residue adhesion.

Other Soldering Flux Product Lineup

| Product number | NS-316F-7 | NS-334 |

|---|---|---|

| Application | Printed circuit boards / harness terminal processing | Hot-dip plating of lead frames |

| Type | ow-residue resin-based | Low-residue organic acid-based |

| Suitable base materials | Copper and copper alloys | Copper and copper alloys |

| Halogen content | - | - |

| Dedicated diluent | NS-700 | NS-700 |

| Soldering method | Flow soldering, dipping | Dipping |

| Remarks | Low-residue, no-clean type. Be sure to control the concentration using the specified thinner. | Low-residue, no-clean type. Be sure to control the concentration using the specified thinner. |

NS-316F-7 (Resin-Based, Low-Residue, No-Clean Flux)

No-Clean / Halogen-Free

NS-316F-7 is a low-residue, no-clean flux developed to eliminate the need for post-solder cleaning processes.

Its halogen-free formulation ensures environmental compliance while maintaining high reliability.

It is compatible with spray fluxers, supports foaming application, and is suitable for dual-wave soldering processes.

Features

Features

・Low-residue, no-clean type

・Effectively suppresses solder balls, bridging, icicles, and other soldering defects

・Allows board inspection even without post-solder cleaning

・Does not interfere with the contact reliability of connectors or switches

・Minimizes equipment contamination and reduces maintenance requirements

Handling Precautions

Handling Precautions

Always perform concentration control when using NS-316F-7 (Dedicated diluent : NS-700).

Concentration control is not required when using spray application.

NS-334 (Organic Acid-Based, Low-Residue, No-Clean Flux)

No-Clean / Halogen-Free

NS-334 is an alcohol-based no-clean soldering flux.

It contains no halogen or resin, and because of its low solid content, it leaves only a minimal amount of inert residue that does not affect electrical performance.

Furthermore, since it contains no water, spattering and splashing during soldering are minimized, and a bright, smooth solder surface can be obtained after soldering.

Features

Features

・Low-residue, no-clean type

・Compatible with various application methods including dipping, spraying, and foaming

・Suitable for both single- and double-sided PCBs (with or without solder coating)

・Ideal for tin plating of insulated wires, stranded wires, and solder coating of printed circuit boards

・Free from rosin and resin

・Enables total cost reduction by eliminating cleaning processes, reducing solvent usage, and lowering labor costs

Handling Precautions

Handling Precautions

Always perform concentration control when using NS-334 (recommended dedicated diluent: NS-700).

Concentration control is not required when using spray application.