NSH63V (NS Heat Cycle Stress Resistant Solder)

NSH63V forms a strong join and displays excellent resistance to heat cycle stress, thus prolonging the working life of various electrical devices.

This solder has proven effective when used with circuit boards that undergo a large amount of heat stress, in-vehicle electrical circuitry, HIC (a metallic Hybrid Integrated Circuit), inverter circuits and CEM-3 circuit boards. For the NS Solder-back Soldering System, we have combined the solder-back nozzle with, generous application of the solder fillet, providing further prevention against cracking. This is the hallmark of this system.

Heat Cycle Stress Test

Conditions : One hour at -55, followed by an hour at 125. Repeated 175 times.

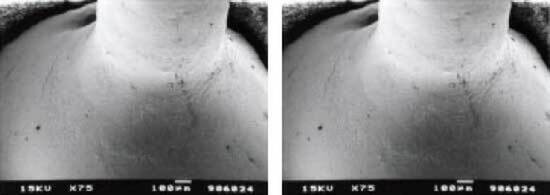

The NSH63V (R) displays no evidence of cracking, unlike the H63A.

Left : NSH63V

Right : H63A (Standard Solder)

Table of Features

| Test Item | NSH63V(R) |

H63A (Comparative Reference) |

Notes |

|---|---|---|---|

| Tensile Strength (MPa) | 86 | 72 | 10mm/min |

| Elongation (%) | Approximately 10% | Approximately 10% | 10mm/min |

| Creep Characteristics | Elongation 100 to 110% | Elongation 70 to 90% |

Load 7.3N/mm² 12 to 17°c |

| Electrical Resistance |

11.9%lACS 0.145μΩ・m |

11.9%lACS 0.145μΩ・m |

- |

| Coefficient of Expansion | 24.7×10-6/℃ | 24.7×10-6/℃ | - |

| Thermal Conductivity | Approximately 50 J/m,s,°c | Approximately 50 J/m,s,°c | - |

| Wetness (Meniscograph) |

Zero Cross : 1.3sec Maximum Wetness : 0.45N/m |

Zero Cross : 1.5sec Maximum Wetness : 0.49N/m |

240°c 5sec Flux Used : NS-316F-7 |

Note : The feature values above were recorded at the time of pressurized burning. Please contact our staff for more details.