TipSave N

Solder Wire (Flux-Cored Solder Wire)

- Melting Point

- 227-229℃

- Alloy

- Sn-Cu-Ni

Products

| Product Number | TipSave N(030) | TipSave N(031) |

|---|---|---|

| Application | Tip wear prevention | Tip wear prevention |

| Type and Features | Silver-freeReduced burning | Silver-freeGood workability |

| Alloy | Sn-0.7Cu-0.05Ni-Ge (+ other) | Sn-0.7Cu-0.05Ni-Ge (+ other) |

| Flux | 030 | 031 |

| Flux Category | ROM1(ROL0) | ROL1 |

| Melting Point | 227-229℃ | 227-229℃ |

| Presence of Halogen Elements | Yes | Yes |

| Expansion Rate | ≧80 | ≧80 |

TipSave N (030)

- Tip wear prevention

- Silver-free / Reduced burning

Reduces soldering tip wear by three times

TipSave N (030) is a flux-cored solder containing a new alloy that reduces soldering tip wear.

By reducing tip wear, it helps eliminate problems such as tip replacement costs, downtime due to tip replacement, and inconsistent soldering quality.

- Melts quickly

- Good for sequential soldering

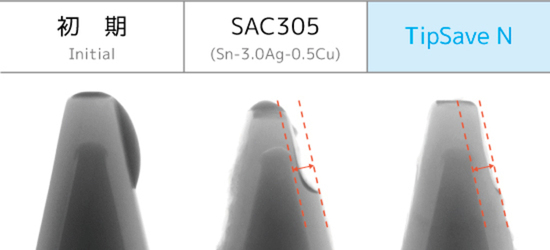

Comparison of tip wear condition after 12,000 joints

Comparison of tip wear condition after 12,000 joints

The image on the left is the results of a test to compare the effects of SAC305 and TipSave N.

Observation of the condition after 12,000 joints shows that TipSave N leaves a thicker layer of plating than SAC305. TipSave N extends the durability of soldering tips by about three times.

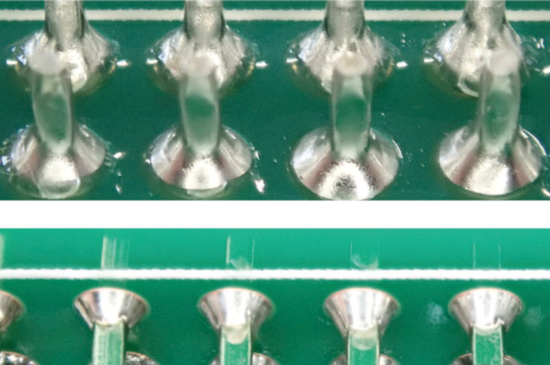

Exhibits wetting and finish equivalent to those of general-purpose products

Exhibits wetting and finish equivalent to those of general-purpose products

・Upper photo : top fillets soldered with TipSave N

・Lower photo : back fillets soldered with TipSave N

We tested TipSave N's solderability with point-to-point soldering on through holes and drag soldering on a connector bridge. It produced beautiful fillets.

TipSave N (031)

- Tip wear prevention

- Silver-free / Good workability

Reduces soldering tip wear and exhibits good solderability

TipSave N (031) is a flux-cored solder containing a new alloy that reduces soldering tip wear. It melts quickly and is great for sequential soldering, thus contributing to improved work efficiency.