SN100C

Solder Paste for Printing Grade

- Melting Point

- 227℃

- Alloy

- Sn-Cu-Ni

Products

| Product Number | SN100C P506 D4 | SN100C P608 D4 | SN100C P900 D3 |

|---|---|---|---|

| Variations | (D4) | (D4) | (D3) |

| Application | General-purpose(D4) | General-purpose(D4) | For (compatible with) formic acid reflow |

| Type and Features | Silver-free12-month shelf life | Silver-freeCompletely halogen-freeLow voiding | Silver-freeCompletely halogen-freeLow voidingLow residue |

| Alloy | Sn-0.7Cu-0.05Ni-Ge | Sn-0.7Cu-0.05Ni-Ge | Sn-0.7Cu-0.05Ni-Ge |

| Melting Point | 227℃ | 227℃ | 227℃ |

| Flux | P506 | P608 | P900 |

| Flux Category | ROM1(ROL1) | ROL0 | ROL0 |

| Presence of Halogen Elements | Yes | Completely halogen-free | Completely halogen-free |

| Particle Size | D4 (Type 4):20-38µm | D4 (Type 4):20-38µm | D3 (Type 3):25-45µm |

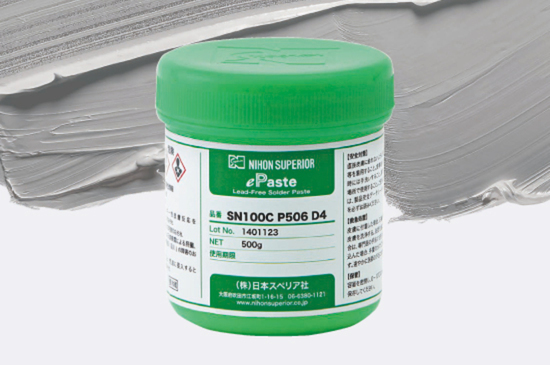

SN100C P506 D4 (D5)

- General-purpose / For micro soldering

- Silver-free / 12-month shelf life

Easy to use with a nice finish. Ideal for a wide range of soldering applications.

General-purpose, lead-free solder paste suitable for a wide range of soldering applications. Its stable viscosity makes it possible to maintain consistent print quality even when repeating storage (refrigeration) followed by use after adding at room temperature. It contains a silver-free, high strength alloy.

- Good quality in repeated printing

- Good wetting

- Prevents chip-side balls

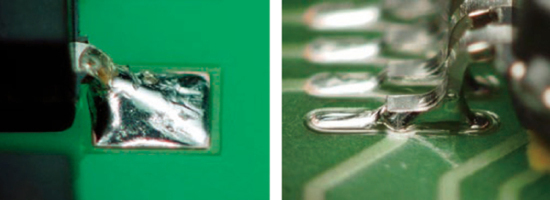

Good wetting at the lead end face

Good wetting at the lead end face

Photo (Left) : SOT23-3 pin

Photo (Right) : 0.4-mm pitch QFP

Exhibits good wetting in unplated lead terminals too, forming nice fillets from the base to tip.

SN100C P608 D4

- General-purpose

- Silver-free / Completely halogen-free / Low voiding

Both environmentally friendly (completely halogen-free) and reliable (reduced voiding)

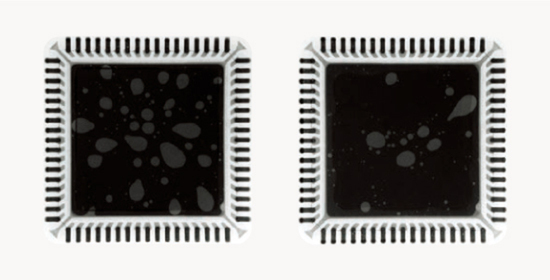

Reduces voiding compared to conventional products

Reduces voiding compared to conventional products

Completely halogen-free solder paste that reduces voids, which cause critical problems in mounting. It exhibits wetting and sequential printing quality equivalent to or better than those of halogen-containing products.

Photo (Left) : Conventional product used (x-ray photo taken after reflow)

Photo (Right) : P608 used (x-ray photo taken after reflow)

SN100C P900 D3

- For (compatible with) formic acid reflow

- Silver-free / Completely halogen-free / Low voiding / Low residue

Exclusively for formic acid reduction reflow. A popular choice for power device bonding.

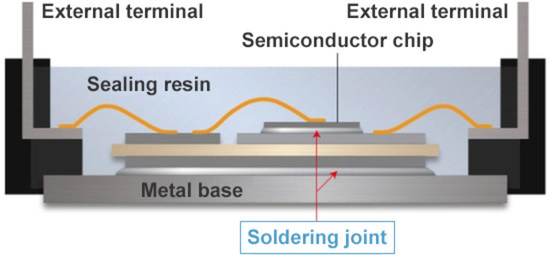

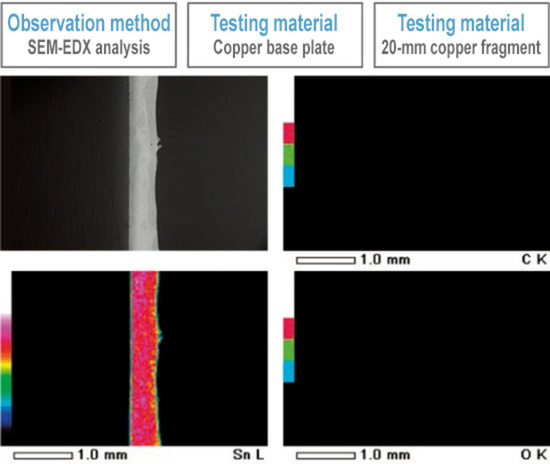

SEM/EDS mapping analysis of soldering joint

SEM/EDS mapping analysis of soldering joint

Halogen-free, ultra-low residue solder paste specially designed for the formic acid reduction reflow process. Ideal for power device mounting that is very sensitive to washing and voiding.

We did not detect any organic substances (carbon) remaining as flux residue.

Application example of SN100C P900 D3