SN100C

Solder Bar

- Melting Point

- 227-340℃

- Alloy

- Sn-Cu-Ni

Products

| Product Number | SN100C | SN100C3 | SN100C4 | SN100CL |

|---|---|---|---|---|

| Application | For BGA, CSP, MCM | For component terminationCompatible with hot temperature soldering | For component terminationCompatible with hot temperature soldering | For fine pitch solderingFor hot air solder leveling |

| Type and Features | Silver-freeGood impact resistance | Silver-free | Silver-free | Silver-freeBridge prevention |

| Alloy | Sn-0.7Cu-0.05Ni-Ge | Sn-3.0Cu-0.05Ni-Ge | Sn-4.0Cu-0.05Ni-Ge | Sn-0.7Cu-0.05Ni-Ge |

| Melting Point | 227℃ | 227-310℃ | 227-340℃ | 227℃ |

SN100C

- For wave soldering / For selective soldering

- Silver-free / Bridge prevention

Our best selling solder bar product

With a 20-year-plus track record, SN100C is our best selling lead-free solder bar that is used all over the world.

- High fluidity

- Excellent wetting

- Prevents shrinkage cavities

- Prevents copper erosion

- Forms stable alloy layer

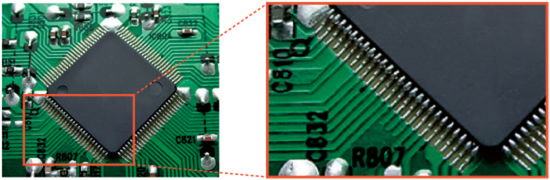

Enables bridge-free soldering

Enables bridge-free soldering

Its excellent wetting and good solder drainage enable bridge-free soldering. The photo shows an example using a 0.5-mm-pitch QFP.Automatic feeding solder wire

Automatic feeding solder wire

We also offer various types of SN100C solder wire used for automatic feeding to solder pots.

Lineup (examples)

- SN100C wire diameter 3.0 mm x 20 kg roll

- SN100CL (for copper concentration adjustment) wire diameter 3.0 mm x 20 kg roll

SN100C3 / SN100C4

- For component termination / Compatible with hot temperature soldering

- Silver-free

Can be used at hot temperatures of up to approx. 400°C

Solder for hot temperature processes suitable for copper lead wires, urethane-coated wires, component termination, etc. The minimal copper erosion helps minimize wire wear in hot temperatures and ultra-fine wire dipping processes. The product also minimizes copper erosion.

SN100CL

- For fine pitch soldering / Compatible with hot temperature soldering

- Silver-free

Ideal for hot air solder leveling on printed circuit boards

Solder for hot temperature processes suitable for copper lead wires, urethane-coated wires, component termination, etc. The minimal copper erosion helps minimize wire wear in hot temperatures and ultra-fine wire dipping processes. The product also minimizes copper erosion.