LF-C2

Solder Paste for Printing Grade

- Melting Point

- 208-213℃

- Alloy

- Sn-Ag-Cu

Products

| Product Number | LF-C2 P608 D4 |

|---|---|

| Variations | (D4) |

| Application | Crack and impact resistant |

| Type and Features | Silver-containingCompletely halogen-freeHigh strengthLow voiding |

| Alloy | Sn-3.5Ag-1.0Cu-3.0Bi |

| Melting Point | 208-213℃ |

| Flux | P608 |

| Flux Category | ROL0 |

| Presence of Halogen Elements | Completely halogen-free |

| Particle Size | D4 (Type 4):20-38µm |

LF-C2 P608 D4

- Crack and impact resistant

- Silver-containing / Completely halogen-free / High strength / Low voiding

Crack-resistant, high-strength solder paste that meets in-vehicle requirements

Crack-resistant, high-strength, lead-free solder paste. Ideal for soldering in-vehicle products and other products that require absolute reliability.

- Crack resistant

- Impact resistant

- Heat cycle resistant

- Reduces voids

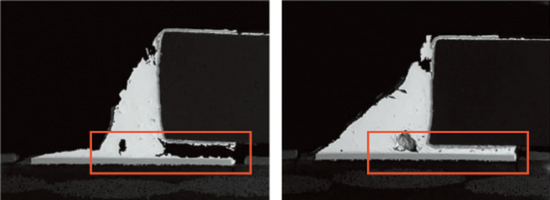

Comparison of fillet cross sections after 2,000 heat cycles

Comparison of fillet cross sections after 2,000 heat cycles

Photo (Left) : SAC305 (Sn-3.0Ag-0.5Cu)

Photo (Right) : LF-C2 (Sn-3.5Ag-1.0Cu-3.0Bi)

LF-C2 maintains a joint state without cracking even after 2,000 cycles (1 cycle: -45°C/+125°C).

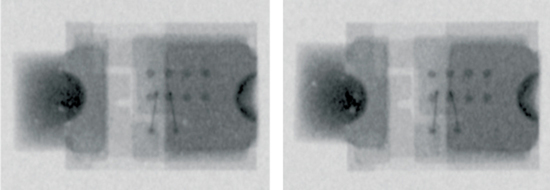

Reduces voiding (compared to SA305)

Reduces voiding (compared to SA305)

Photo (Left) : SAC305 (Sn-3.0Ag-0.5Cu)

Photo (Right) : LF-C2 (Sn-3.5Ag-1.0Cu-3.0Bi)

LF-C2 reduces voiding that causes problems in surface mounting.

Satisfies requirements for in-vehicle product reliability