SN97C

Solder Paste for Dispensing Grade

- Melting Point

- 218-219℃

- Alloy

- Sn-Ag-Cu

Products

| Product Number | SN97C P603 D4 | SN97C P613 D5(D6)(D7) |

|---|---|---|

| Variations | (D4) | (D6) |

| Application | General-purposeFor micro soldering | For Jet DispensingFor micro soldering |

| Type and Features | Silver-containingCompletely halogen-free | Silver-containingCompletely halogen-free |

| Alloy | Sn-3.0Ag-0.5Cu | Sn-3.0Ag-0.5Cu |

| Melting Point | 218-219℃ | 218-219℃ |

| Flux | P603 | P613 |

| Flux Category | ROL0 | ROL0 |

| Presence of Halogen Elements | Completely halogen-free | Completely halogen-free |

| Particle Size | D4 (Type 4):20-38µm | D5 (Type 5):10-25µm / D6 (Type 6):5-15µm / D7 (Type 7):2-11µm |

SN97C P613 D5(D6)(D7)

- For Jet Dispensing

- Silver-containing / Completely halogen-free

P613 Series Designed for High-Speed, Non-Contact Jet Dispensing

A solder paste formulated specifically for high-speed jet dispensing applications.

Available in three powder size options (Type 5 / 6 / 7).

It maintains excellent shape retention even at high dispensing speeds, ensuring stable solder joints with precise and consistent volumes.

・High-speed dispensing: 30–7 shots/sec

・Supports ultra-fine dots: φ250–300 µm

・Completely halogen-free

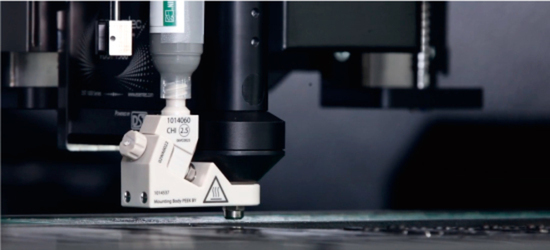

Co-Developed with ESSEMTEC

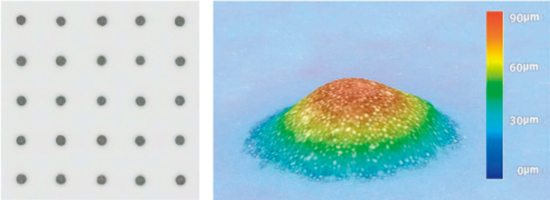

Solder Print Appearance

Solder Print Appearance

Image:Dispensed dot diameter φ280 µmSolder Melting Characteristics

Solder Melting Characteristics

Left:Cu(OSP)

Center:Cu

Right:Ni

Exhibits excellent wettability and melting performance on various substrate materials, contributing to stable and consistent production quality.

SN97C P603 D4

- General-purpose / For micro soldering

- Silver-containing / Completely halogen-free

Greater continuous dispensing capability due to enhanced activation

Completely halogen-free, dispenser-type solder paste with improved continuous dispensing capability and solder meltability due to enhanced activation.

- Good continuous dispensing capability

- Good meltability

- Completely halogen-free

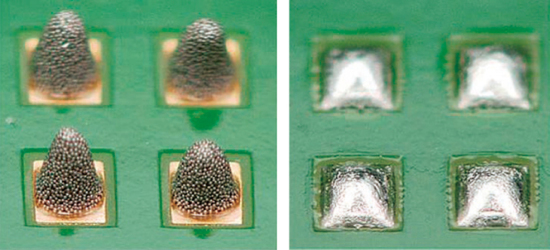

Solder meltability (photos taken after dispensing and after reflow)

Solder meltability (photos taken after dispensing and after reflow)

Photo (Left) : after dispensing (R1608)

Photo (Right) : after reflow

Dispensing volume is stable, and its superior meltability ensures reliable bonding.